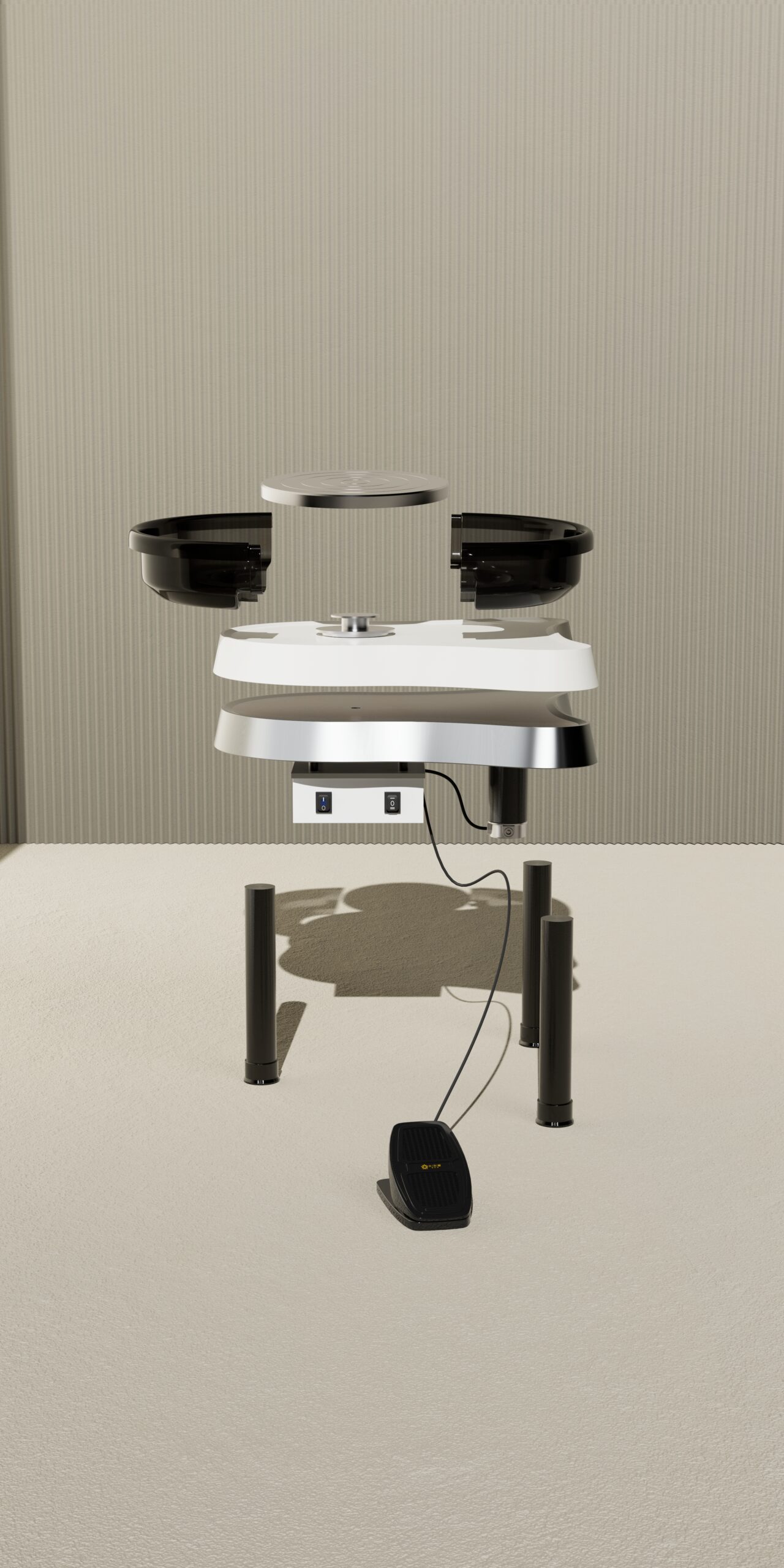

potter’s wheel (intelligent – linked model)

External dimensions: L65 * W63 * H52 cm (including the height of the water basin)

Turntable: Aluminum alloy anti – rust turntable, with a diameter of Φ32 cm and a thickness of 2.5 cm

Water basin: Diameter Φ46.5 cm

Working voltage: AC220V

Power: 380W

Rotational speed: 0 – 320r/min

Stability: The run – out of the aluminum disc is ≤0.05 mm

Whole – machine noise: ≤48 dB

Net weight of the product: ≈20 KG

Speed – adjusting method: Hall – effect foot – pedal speed control, liquid – crystal touch – screen switch, multi – machine linkage

Rotation direction: Both forward and reverse rotations are possible

The motor adopts a 380 – W high – power motor.

Product description:

The potter’s wheel adopts a new linkage effect. One main machine can control multiple potter’s wheels, and all potter’s wheels follow the operation of the main machine, so there is no need to worry about other people randomly pressing the buttons anymore.

The frame of the potter’s wheel uses an ABS plastic tabletop, and the carbon – steel frame is easy to clean and rust – proof. It is formed in one – time molding, effectively waterproof, and has a stable structure. The feet of the potter’s wheel use iron die – casting elements as supports, which have high hardness and strong firmness, ensuring the smooth and stable operation of the whole machine. High – molecular anti – vibration foot pads are also used, which are not only beautiful but also can reduce the noise generated during use.

The motor of the potter’s wheel adopts an ultra – quiet three – phase AC variable – frequency motor. After the motor runs smoothly at a no – load state with a rotational speed of 50HZ, 16500 ± 700R/min, the measured noise limit is ≦65db. The speed control system uses PWM control to realize speed adjustment with a movable foot – pedal, which can realize variable – speed adjustment from 0 – 300/min, is energy – saving and power – saving, and has a large – torque output. The motor has passed a 50,000 – hour service – life test, and is of reliable and stable quality. The speed control makes the motor run accurately through the traditional linear acceleration – deceleration control system without delay in acceleration and deceleration. Through bidirectional adjustment by the controller and the main control panel, it can start and stop suddenly.

The turntable adopts an oversized 320φ aluminum disc. After the die – casting and grinding process, the surface is flat and smooth without pores, ensuring that the works are placed stably during the operation of the whole machine and the operation is comfortable.

The water basin is formed by engineering injection molding with good fluidity and high weather resistance. The impact strength reaches 107J/M at – 20℃. This material has the characteristics of high fluidity, good smoothness, and excellent high – temperature resistance, making the inner side of the water basin smooth and flat and easy to clean quickly. It has corrosion – resistance, durability, anti – deformation, and appropriate grip, which improves the feel of disassembly and installation.

The foot – pedal adopts a Hall – effect foot – pedal that can be stepped on 100,000 times. It has leakage – proof and waterproof devices, and the structure is more stable. At the same time, a star – shaped support structure is added at the bottom, which not only ensures that the aluminum disc structure is more solid and stable but also effectively reduces the heaviness. Finally, through concentric processing by a numerical – control lathe, the aluminum disc and the motor spindle are coordinated more harmoniously, ensuring that the potter’s wheel process is more stable.

The product switch adopts a dual – control foot – pedal button, which has an integrated and beautiful shape and is safer and more convenient to use. The forward – reverse switch not only effectively improves the safety of the product but also makes the potter’s wheel as a whole more beautiful, and the manual and foot – pedal control can be switched more conveniently.

A leakage – proof protection plug is adopted to ensure the safety of customers to the greatest extent.

The product has passed the quality inspection by relevant national departments.

Related products

- Rated 0 out of 5

LCD touch pottery wheel LP-19.

- Rated 0 out of 5

potter’s wheel (“Direct – Drive)

- Rated 0 out of 5

potter’s wheel (intelligent – linked

- Rated 0 out of 5

LPJ-ZND01